In the manufacturing sector, the COO is responsible for ensuring that business operations are efficient and effective and that the proper management of resources, distribution of goods and services to customers, and analysis of queue systems is conducted.

His goals are achieving the expected results in terms of timing, volumes, quality and compliance to the product design and to the requested order, for all Operations areas within the company. Reporting to the CEO, the COO leads the Production, Logistics, Quality, MES, Purchase and R&D areas.

FLEX for Operations Management

In manufacturing companies, in particular those having a Make-To-Order or Engineering-To-Order approach the Technical and Design Office Manager has the following tasks:

-

approval (together with the Top MAnagement or CEO) of customer requests

-

problem solving

-

definition of quotation, prices and delivery dates

-

technical drawing creation (Cad/Cam)

-

product development

-

coordinating the designing activities

-

operational development of technical drawings

-

sampling

-

workforce management in the work-shop

-

supplier management

-

machinery supervision and setup

(Source: Isfol 2010)

FLEX for Operations Management

The Purchasing Manager or Procurement Manager

A Purchasing Manager is an employee within a company, business or other organization who is responsible for buying or approving the acquisition of goods and materials needed for production, general supplies for offices and facilities, equipment, or construction contracts.

A Purchasing Manager's responsibilities may include:

-

supporting purchasing objectives and budget definition

-

seeking reliable vendors or suppliers to provide quality goods at reasonable prices

-

negotiating prices and contracts

-

reviewing technical specifications for raw materials, components, equipment or buildings

-

determining quantity and timing of deliveries (more commonly in small companies)

-

forecasting upcoming demand.

(Source: Isfol 2000)

FLEX for Operations Management

Operational roles

Thera are also a lot of operational roles involved in the Operations management process, such as:

-

The Time and Motions responsible

-

The Designer

-

The R&D operator

-

The Product Engineering responsible

-

The Sales agent

-

The Sales office assistant

-

The Buyer

-

The Purchasing office assistant

-

The Responsible for Receiving

-

The Responsible for Shipment

-

The Warehouse Operator

-

The Inventory manager

FLEX for Operations Management

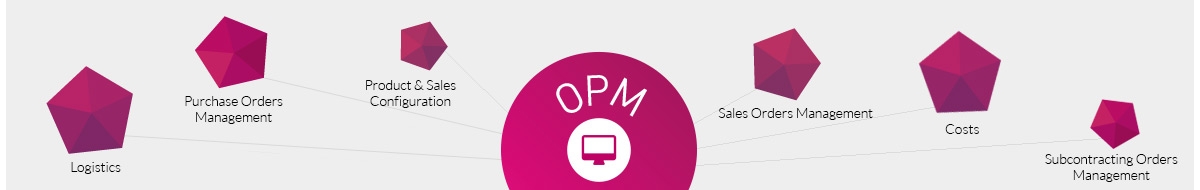

FLEX Role-based features for Operations Management

Thanks to the Role-based features, FLEX provides monitoring and analysis features for different business roles.

These features can be activated both on the system entry application, and on specific configurable dashboards, through multi-panel interfaces.

Each business role in a company has, therefore, a real-time access to features, information and KPIs, useful for his job.

An example of the information and KPIs available for Operations management are:

• Daily value of inventory receipts from production in the last N days

• Production resources' Saturation level

• Sales orders' daily value

• Value and Margin of shipped goods in a week

• Alert on orders readty for shipping

• Number of bids

• Design activities workload (in combination with J-Flex APS)

• Raw materials quotation trend in real-time (from web)

• Missing materials for solicit to providers

• ecc.

Advanced configuration tools: FOR YOU!

Thanks to the configuration features of FLEX, the user does not only have to opportunity to choose the most appropriate business role among the ones available in the default configuration system, but can also configure and personalize his role and his dashboards on his own. By using the "FOR YOU" Advanced Application Tools, in fact, each user can independently manage and modify an existing configured role as well as build his own working panels, by selecting the features he needs from the User Application Panel.