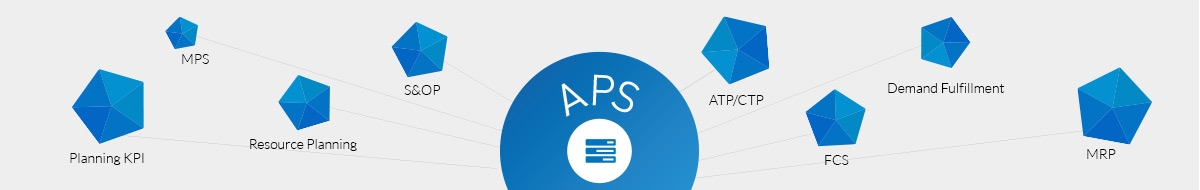

FLEX APS is the manufacturing planning and scheduling software solution, that supports all company planning processes from master planning to scheduling.

Interactive

The Flex APS solution provides innovative features for production planning by replacing the traditional "Sequential Planning" approach with the new “Concurrent Planning”approach.

Thanks to this approach, several planning tools are integrated on a single Planning Workplace so that users can istantaneously and easily modify the simulation context, according to the related objectives.

It is possible to make changes not only on the graphical views (Gantt Diagram) but also on the development environment, working on the algorithms.

Simulative

Flex APS provides planning simulation features, in order to operate a confrontation between different production plans and scenarios. This is particularly useful to take proper decisions and choose the best production plan.

Thanks to the Planning KPI module, in fact, it is possible to easily understand the impact , in terms of performance, of a specific decision taken about the production plan.

Once a production plan has been generated, it is possible to see the impact of the same on a set of KPIs.

Each simulation plan and the related KPI dashboards, can be saved in order to make a comparison and choose the best plan.

Real time

FLEX APS – by exploiting the synergy assured by the co-development with the MES application (Manufacturing Execution System) – fully embodies the “Plan while Executing” paradigm, so that every planning decision can be immediately executed on the Shop Floor, and viceversa, every low-level event may affect immediately the decision panel.

FLEX APS works in real-time with Flex MES (J-Flex PWE solution) but it can also be integrated with third-part MES applications and it can be easily integrated with the company existing ERP systems (SAP, Baan, Microsfot Dynamics, JDEdwards, AS400, etc).